Company Profile

About Us

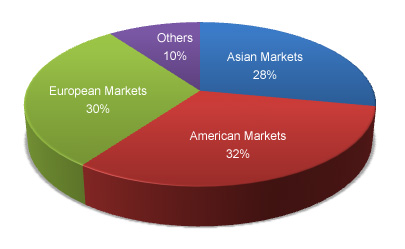

Seika Electric Co., Ltd. is founded in 1973 as an ISO 9001 / ISO 14001 certified factory and has become a leading manufacturer in the field of capacitors in Asia. Products have been enjoying a great reputation from all of our customers worldwide. Seika is specialized in the manufacturing of Metallized PE and PP film AC capacitors and Motor Starting Electrolytic Capacitors applicable for electrical apparatus and home electrical appliances such as air-conditioners, compressors, refrigerators, laundry washers, dish washers, blowers, exhaust fans, electric fans, ceiling fans, remote controls, pumps, UPS, electrical power tools, fluorescent lamps, mercury lamps… The factory is equipped with the most up-to-date facilities imported from Switzerland and Japan; we also adopt the Japan made high quality film and relevant raw materials. Products have been approved by UL, CUR, VDE, IMQ and have won CB / EN60252-1 certificate. With the merits of monthly production ability of above 5 million pcs., flexible production ability, wide range of product specifications, reliable quality assurance, excellent management system, and exact delivery, we are able to offer you satisfactory products and service. |

|

Capacitor Manufacturer

Seika Electric Co., Ltd. is superior Passive Components Manufacturer in Taiwan, supplying Protective Capacitor, Power Capacitor and Electronic Terminal with superior quality. We offer Capacitor for AC Motor and Electric Fan use; superior quality is guaranteed. If you are searching for high quality Power Capacitor and Protection Capacitor Manufacturer, please do not hesitate to contact us.

‧ Main Products:

Certificate

| Certificate | Safety | Class | Max. Temp. | Series | Capacitance Range | Voltage Range | Model Type | Licence No. |

| VDE HSFPU | P0 | C | 70 | MK | 1uF~40uF | 150Vac~300Vac | BM, BT, BL, RE… | VDE:104897 |

| CB:DE1-6355 | ||||||||

| VDE HSFPU | P0 | C | 70 | MK | 1uF~5uF | 350Vac~400Vac | BM, BT, BL, RE… | VDE:104896 |

| CB:DE1-6354 | ||||||||

| VDE GPFPU | P0 | C | 85 | MK | 0.1uF~40uF | 150Vac~450Vac | BM, BT, BL, RE… | VDE:116769 |

| CB:DE1-32461 | ||||||||

| VDE GPFNT | P0 | B | 85 | MK | 0.1uF~40uF | 150Vac~450Vac | BM, BT, BL, RE… | VDE:116769 |

| CB:DE1-34021 | ||||||||

| VDE HPFMS | P0 | A | 85 | MK | 0.5uF~5uF | 400Vac | BM, BT, BL, RE… | VDE:40008138 |

| VDE HMFMS | P0 | A | 100 | MK | 0.5uF~16uF | 150Vac~400Vac | BM, BT, BL, RE… | VDE:40023787 |

| CB:DE1-39113 | ||||||||

| VDE HSFPU | P0 | C | 70 | MKP | 1+1uF ~ 12+12uF | 150Vac~300Vac | BM, BT, BL, RE… | VDE:104893 |

| CB:DE1-6352 | ||||||||

| VDE GPFMS | P0 | A | 85 | MK | 0.3+0.3 ~ 9+9uF | 150Vac~450Vac | BM, BT, BL, RE… | VDE:40019985 |

| CB:DE1-38526 | ||||||||

| VDE HSFPU | P2 | C | 70 | RU | 3uF~50uF | 150Vac~450Vac | RUP, BM, BT, RE… | VDE:94696 |

| VDE GPFNT | P2 | B | 85 | CP | 0.5uF~70uF | 150Vac~450Vac | RUP | VDE:40019357 |

| CB:DE1-36130 | ||||||||

| VDE GPFPU | S3 | C | 85 | CP | 0.5uF~10uF | 150Vac~450Vac | BM, BT, BL, RE… | VDE:40001022 |

| CB:DE1-34259 | ||||||||

| VDE GPFNT | S3 | B | 85 | CP | 0.5uF~20uF | 150Vac~450Vac | BM, BT, BL, RE… | VDE:40040804 |

| CB:DE1-54635 | ||||||||

| IMQ HSFPU | P0 | C | 70 | MK | 1uF~5uF | 350Vac~400Vac | BM, BT, BL, RE… | IMQ: V2791 |

| IMQ GPFNT | P0 | B | 85 | MK | 0.5uF~10uF | 350Vac~450Vac | BM, BT, BL, RE… | IMQ: V4750 |

| IMQ HMFNT | P0 | B | 100 | MKR | 1.5uF~3uF | 400Vac | BM, BT, BL, RE… | IMQ: V4721 |

| CB:IT -1942 | ||||||||

| CQC GPFNT | P0 | B | 85 | MK | 0.5uF~40uF | 400Vac | BM, BT, BL, RE… | CQC 07002021362 |

| CQC HMFMS | P0 | A | 100 | MK | 0.5uF~16uF | 400Vac | BM, BT, BL, RE… | CQC 09002040210 |

| CQC GPFNT | P0 | B | 85 | MK | 0.1uF~22uF | 450Vac | BM, BT, BL, RE… | CQC 11002061114 |

| CQC GPFNT | P2 | B | 85 | CP | 0.5uF~20uF | 400Vac~450Vac | BM, BT, BL, RE… | CQC |

|

|

|

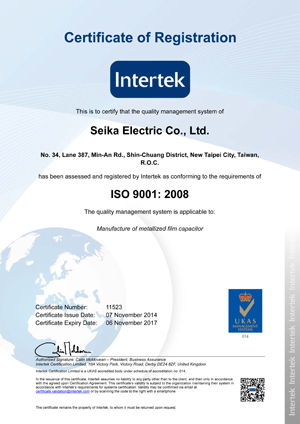

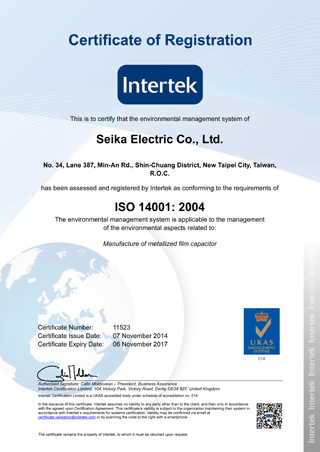

| ISO9001 Certificate | ISO14001 Certificate |

Quality policy

| Follow ISO 9001 Quality Policy Follow IS0 14001 Environmental Protection Policy |

|

| Environmental Policy | |

◇ |

Complying with Environment Laws and Regulations: |

| Observe relevant environment laws and regulations and open unobstructed communication channels to the surroundings. | |

◇ |

Recycling and Reproduction: |

| Exert the manufacturing efficiency of our company and increase recycling and reuse natural resources | |

◇ |

Sustainable Improvement: |

| Prevent pollution from production by reducing wastes and develop new recycling technologies of recycling and reuse of natural resources | |

◇ |

Reducing the Impacts on the Environment: |

| Adopt new strategies on reducing pollution to lessen environmental impact | |

Histroy

| 1973 | Specialized in the manufacturing of Metallized Film Capacitors used in AC electrical appliances. |

| 1978 | Founded the subsidiary company, Hantai Electric Co., Ltd., specialized in the manufacturing of Motor Starting Capacitors. |

| 1981 | Found the other affiliated enterprise, Welley Solder Corp. manufacturing Active Rosin Cored Solder Wires, Solder Bars, Pure Zinc Wires, and Tin Zinc Alloy Wires. |

| 1990 | Founded Thai Seika Electric Co., Ltd. In Thailand specialized in the manufacturing of Metallized Film Capacitors . |

| 1993 | Being registered as an ISO 9002 Certified Manufacturer. |

| 1994 | Started to produce P2 Segment Margin film Protective Capacitors and had obtained a 10-Year Patent in Taiwan area. |

| 2002 | Being registered as an ISO 9001 Certified Manufacturer. |

| 2004 |

Being registered as an ISO 14001 Certified Manufacturer and gradually started to adopt RoHS-Compliant manufacturing process. |

| 2008 | Started to proceed REACH environmental policy. |

Customers